About Hanging Platform

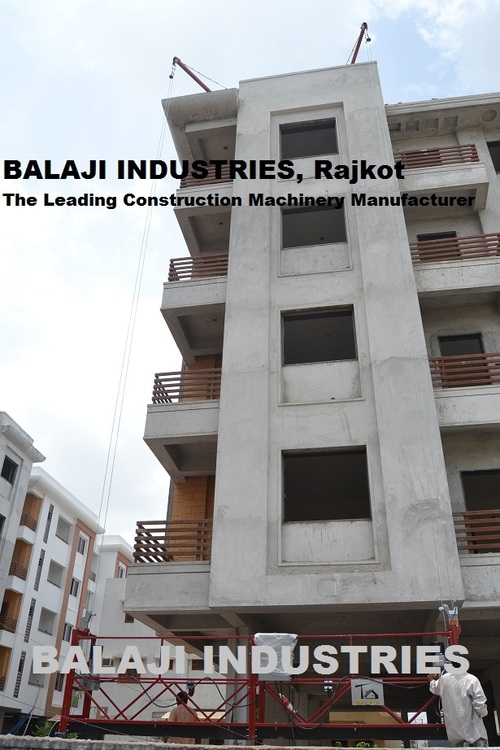

By incorporating international standards of business integrity in our production process, we are able to manufacture, supply and export Hanging Platform. These products are specially designed for temporary as well as permanently applications for lifting people and their working equipment at unlimited heights. The complete system of these products consists of working platform equipped with two electric hoists and the safety lock. In order to prevent loose wire rope damaging the elevation, these products have suspended by wire ropes from a suspension structure. Hanging Platform is available with us in different specifications as per the needs of the clients.

Application areas:

- Cleaning

- Concrete repair

- Cladding

- Inspection

Suspended Working Platform / Swing Stage / Cradle |

Temporarily Installed Suspended Access Equipment, also known as Suspended Platform or Temporary Access Equipment, is a kind of construction machinery for high-rise construction. It's a lightweight rigid Steel/Aluminum made object capable of carrying persons onto a certain height so as to facilitate the aerial work.

ZLP series platforms developed and produced by are CE certified and provide safer, easier and more efficient work platforms for your workers. They are ideal for plaster, painting, repairing, decoration, cleaning, elevator installing, loading heavy row materials to higher grounds, etc. It is also widely used in the construction works of big-size tank, bridge, dam and chimney. Our suspended platform machinery helps improve working efficiency, and fast construction at reduced cost. Along with standard platforms we also manufacture Special Suspended Working Platforms with 90 degree, 45 degree and Circular shapes. We can also manufacture platforms as per client's specific requirements. TechnicalSpecification | | | | | | | Model Type | ZLP630 | ZLP800 a Type | ZLP800 S Type | ZLP1000 | Rated Load Capacity (kg) | 630 | 800 | 800 | 1000 | Rated Lift Speed (m/min) | 9~11 | 8 | 8~10 | 8~10 | Length of Platform (m) | 6 | 7.5 | 7.5 | 7.5 | Wire Rope Diameter | 8.3 mm, 4*31SW+Fc | 8.6 mm, 6*19+IWS | 8.6 mm, 6*19+IWS | 8.6 mm, 6*19+IWS | Hoist | Model Type | LTD 6.3 | LTD 8 | LTD 8 | LTD 10 | Rated Lift Force (KN) | 6.17 | 7.84 | 7.84 | 9.8 | Motor | Power (KW) | 1.5 | 1.8 | 2.2 | 3 | Voltage | 415 V 50 Hz

3-Phase | 415 V 50 Hz

3-Phase | 415 V 50 Hz

3-Phase | 415 V 50 Hz

3-Phase | Frequency (Hz) | 50 | 50 | 50 | 50 | Rotate Speed (rpm) | 1420 | 1420 | 1420 | 1420 | Breake Torque (KN) | 15 | 15 | 15 | 15 | Safety Lock | Permissible Force of Impact (kN) | 30 | 30 | 30 | 30 | Fall Distance Permitted (mm) | < 100 | < 100 | < 100 | < 100 | Tilt Angle Permitted | 3~8 | 3~8 | 3~8 | 3~8 | Suspension Mechanism | Projecting Length of the Front Beam (m) | 1.3~1.7 | 1.3~2 | 1.3~2 | 1.3~2 | Adjustable Height of the Support Beam (m) | 1.35~2 | 1.35~1.7 | 1.35~1.7 | 1.35~1.7 | Weight | Steel / Aluminum Platform (kg) | 450 / 300 | 500 / 400 | 560 / 400 | 600 / 450 | Suspension Mechanism (kg) | 360 | 360 | 360 | 360 | Counter Weight (kg) | 900 | 1000 | 1000 | 1300 |

|

Versatile and Customizable PlatformThis hanging platform can be tailored to your specific needs, with customizable lengths from 2 m up to 7.5 m and width options of 0.7 m or 0.8 m. The adaptable system ensures suitability for a wide range of construction, maintenance, and facade applications, providing both flexibility and safety.

Reliable Safety and PerformanceEquipped with a strong steel wire rope, CE certification, and an advanced push-button control box, the platform prioritizes operator safety and ease of use. The system is engineered for low noise (80 dB) and smooth electric hoisting, while shock resistance and a high lifting capacity ensure reliable operation for demanding site conditions.

Durable Construction and Efficient OperationDesigned with high-strength materials, powder-coated or galvanized for rust resistance, this platform is built for longevity. Its three-phase asynchronous motor and low power consumption (2.2 kW) enable efficient lifting up to 100 m, with easy installation thanks to a standardized handle and swivel casters with brakes.

FAQs of Hanging Platform:

Q: How can the length and width of the hanging platform be customized?

A: The platform offers adjustable lengths from 2 meters to 7.5 meters and width options between 0.7 meters and 0.8 meters. During the ordering process, you can specify your desired dimensions to best suit your project requirements.

Q: What is the main usage of this construction hanging platform?

A: It is primarily used for construction, building maintenance, facade cleaning, and repair work, providing safe and stable access to elevated work areas up to 100 meters high.

Q: When should this platform be chosen over traditional scaffolding?

A: The hanging platform is ideal when quick installation, greater mobility, and reduced labor costs are needed, especially for high-rise structures where traditional scaffolding may be less practical or more time-consuming to set up.

Q: Where can this platform be installed and used safely?

A: It can be securely installed on building roofs or other sturdy overhead structures using its adjustable beam and counterweight suspension mechanism, making it suitable for commercial, industrial, or residential building projects.

Q: What process is involved in setting up the platform on site?

A: Installation involves assembling the adjustable suspension mechanism, securing the counterweights, attaching the platform sections with steel wire ropes, and connecting the electric hoist and control box. Final safety checks are conducted before operation.

Q: How does the platform ensure safety during operation?

A: Safety features include a CE-certified design, a shock-resistant frame, fixed rotation platform, reliable push button controls, and a maximum noise level of 80 dB, along with the use of high-strength, rust-resistant materials and secure wire rope belts.

Q: What benefits does this platform offer to construction professionals?

A: It delivers easy operation, high lifting capacity, quick installation, and long service life. Its rust-resistant construction and efficient power use further enhance productivity and reduce maintenance requirements.